Top 7 Latest Trends in CNC Plasma Cutting Machines for 2025

Table of Contents

Introduction Rise of smart automation in CNC plasma cutting Integration of AI and machine learning Advancement in torch technology Focus on energy efficiency and sustainability Enhanced precision and cutting speed Expansion of portable CNC plasma machines Growth of cloud-based CNC control systems ConclusionIntroduction

CNC plasma cutting machines are becoming smarter, faster, and more energy-efficient.

AI and automation improve accuracy, speed, and overall productivity.

Portable and cloud-connected machines increase flexibility and remote control.

Indian manufacturers are leading innovation in advanced CNC plasma cutting solutions.

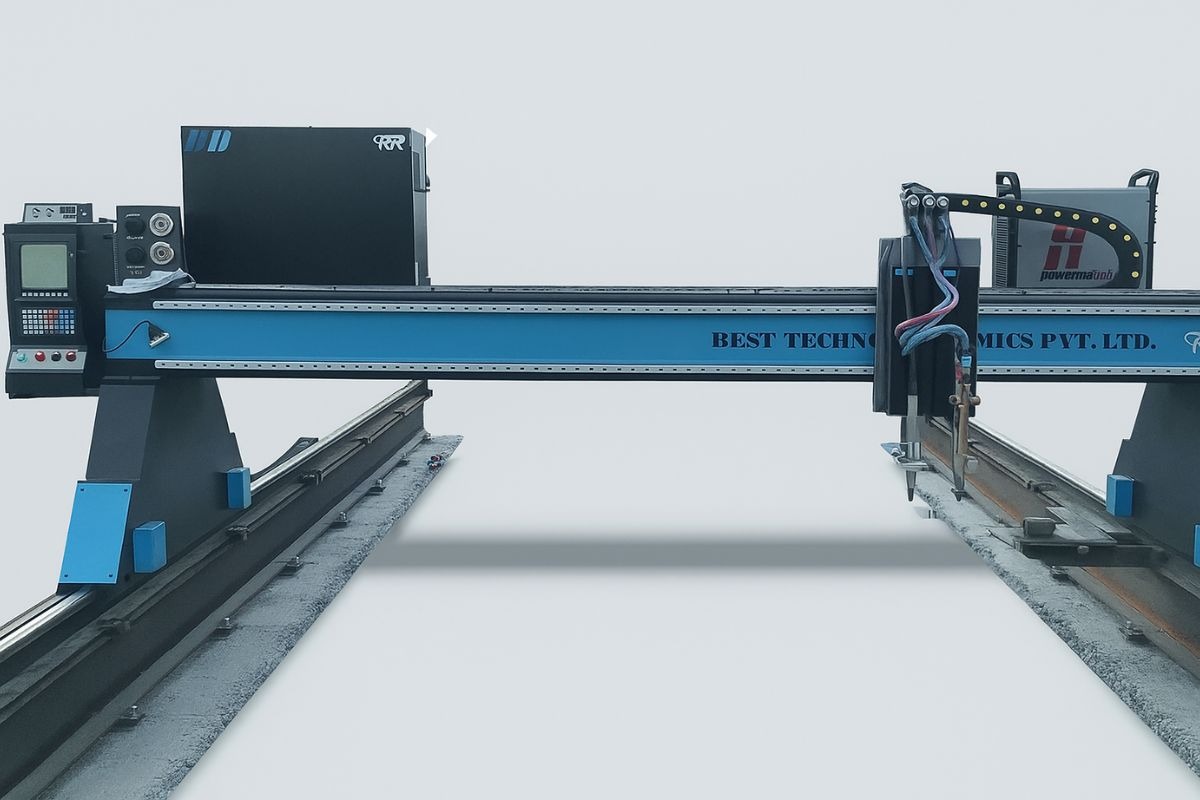

The metal manufacturing industry is expanding at a very fast rate, with the CNC plasma cutting machine at the forefront. With the continuous development of digital technology, manufacturers now apply smart and sharp systems for better performance. In 2025, fresh innovations are enhancing precision and efficiency. Most CNC plasma cutting machine manufacturers in India are developing automated, AI-based, and environmentally friendly solutions. Here are the top seven trends that are revolutionizing CNC plasma cutting machines this year.

Rise of smart automation in CNC plasma cutting

Smart automation is one of the most apparent trends in 2025. CNC plasma machines now have automated loading and unloading mechanisms, minimizing human effort and time.

New-age controllers are capable of automatically changing cutting parameters based on material type, thickness, and complexity of design. This speeds up the process and reduces the error rate.

Principal advantages are:

- Lower labor costs

- Increased accuracy

- Uniform output quality

- Less down time attributable to automated error checking

Therefore, automation is the new norm for industries that want to increase production without sacrificing precision.

Integration of AI and machine learning

Machine Learning (ML) and Artificial Intelligence (AI) are now fuelling innovation in CNC plasma cutting machines. Technologies enable the machines to learn from previous cuts, estimate future problems and automatically correct themselves.

AI-based software can provide optimized cutting paths, which lead to reduced material waste and improved efficiency. Moreover, AI-driven predictive maintenance decreases machine failure and extends lifespan.

For example, a number of CNC machine dealers in Vadodara are already offering AI-based systems, which are analyzing cutting data in real time to enhance performance. This AI integration is giving plasma cutting more intelligence and reliability than ever before.

Advancement in torch technology

The cutting torch has also seen major improvements over the last few years. Advanced plasma torches now contain better arc stability, quicker ignition systems, and greater cooling systems. These characteristics enable prolonged life and more predicated results for the torch.

Advanced torches are being made in 2025 to cut a wide variety such as aluminum, stainless steel and copper. Furthermore, new torches are capable of walking with low gas consumption, resulting in low operational expenses.

Benefits of advanced torch systems:

- Enhanced cut quality

- Increased component life

- Reduced maintenance expenses

- Multi-material compatibility

However, this advanced torch technology ensures manufacturers get cleaner cuts and smoother edges with less effort.

Focus on energy efficiency and sustainability

With industries striving toward sustainability, energy-efficient plasma cutters are in demand. The latest CNC plasma cutting machines are capable of consuming low power while providing high cutting speeds.

Producers are adopting environmentally friendly gases and materials that reduce emissions when in operation. Energy-efficient power sources also contribute to reduced total electricity consumption.

Furthermore, most new plasma systems today possess auto-shutdown functions that save energy when the equipment is not in use. This trend is a testament to increased awareness of environmental stewardship among metal fabrication producers.

Enhanced precision and cutting speed

Accuracy has always been the soul of CNC plasma cutting. But in 2025, technology has elevated accuracy to a new height. Better servo drives, quicker communication between the motion systems and control unit, and real-time monitoring have all helped make the cuts more accurate.

Additionally, plasma cutters now come up with high-definition (HD) cutting systems that can produce smooth edges and more wide work even at high speed. As a result, after the processing efforts are low and the production time is fast.

Advantages of increased precision include:

- Less material waste

- Less rework requirement

- Increased part quality

- Increased project turnaround

Moreover, this transition towards precision-cutting assists industries to easily achieve stringent quality requirements.

Expansion of portable CNC plasma machines

Another major trend that is gaining momentum is the rise of portable CNC plasma cutting machines. These lightweight, compact units are ideal for small workshops, fieldwork and on-site maintenance projects.

Therefore, portable units are now fitted with refined digital control, touchscreen and Wi-Fi connectivity. This enables operators to operate easily for future use and operate design files.

Additionally, their cost-effectiveness and portability makes them a popular option between startups and small enterprises that cannot invest in large cutting systems.

Why portable CNC plasma machines are popular:

- Easy to move around

- Low installation fee

- Easy-to-use interface

- Ideal for varied applications

The rising need for flexibility and mobility has fueled this trend in different manufacturing industries.

Growth of cloud-based CNC control systems

Cloud technology is revolutionizing the way CNC plasma cutting machine function. Contemporary systems are now coupled with cloud-based control systems that enable operators to monitor and control cutting processes remotely.

Through cloud connectivity, users are able to access design libraries, measure performance data, and refresh machine software at any time, anywhere. This digital experience guarantees enhanced collaboration between production and design teams.

Additionally, cloud-based systems provide data storage solutions that increase productivity and clarity. They allow companies to monitor cutting efficiency, identify patterns, and adjust workflow.

For example, most of the CNC plasma cutting machines made in India now provide cloud-ready models with remote operation and diagnostic support that enables swift troubleshooting and less downtime.

Conclusion

The CNC plasma cutting sector is transforming rapidly in 2025 with AI, automation, and energy-saving technology. These improvements make equipment intelligent, quicker, and more economical. Innovative CNC machine traders in Vadodara and Indian makers propel innovation, assisting industries toward greener, more accurate, and efficient metal fabrication for the future.