What Is a CNC Plasma Pipe Profile Cutting Machine and How Does It Work?

Table of Contents

- Key takeaways

- What is a CNC plasma pipe profile cutting machine?

- Why is this machine important in modern fabrication?

- How does a CNC plasma pipe profile cutting machine work?

- Main components involved in the cutting process

- Where are these machines commonly used?

- How to choose the right machine?

- Why Best Techno Dynamics?

- Conclusion

- Frequently Asked Questions

Key takeaways

- CNC plasma pipe profile cutting machines deliver accurate and repeatable pipe cuts

- Automation ensures accuracy and saves time in productions

- Plasma technology results in clean and smooth edges

- Trusted manufacturers provide greater long-term value

A CNC pipe profile cutting machine is a machine that cuts pipes precisely by computer control and plasma heat. It assists manufacturers in developing clean shapes, angles, and joints in a short period of time. Since it is an automated process, it minimizes errors and time and enhances the quality of production. Therefore, it is popular in contemporary industrial fabrication.

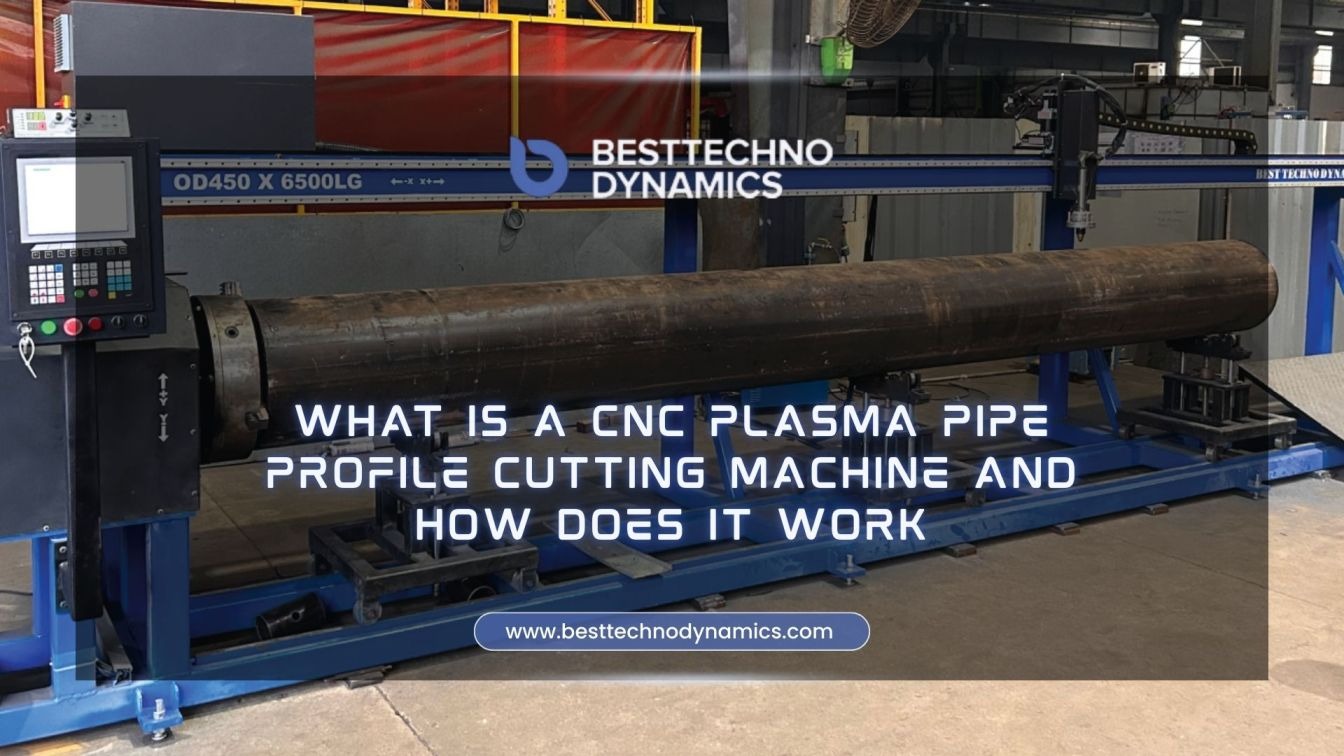

What is a CNC plasma pipe profile cutting machine?

A CNC plasma pipe profile cutting machine is a computer-controlled machine that is used to cut round or square pipes into the desired shapes. The machine has digital instructions that direct the cutting torch to move as opposed to manually cutting.

This machine has the advantage of cutting with a high-temperature gas, plasma, as opposed to the conventional methods of cutting. This plasma fuses metal in a fast and clean manner. Consequently, the cut edges are smooth and can be welded or assembled.

Additionally, this machine is primarily applied in areas where precision is important, including pipe joints, branch connections, and complicated profiles. These machines are designed by companies such as Best Techno Dynamics to be able to cope with the workload of an industrial level but make their operation easy.

Why is this machine important in modern fabrication?

The industries today require speed, precision, and consistency. These expectations cannot be fulfilled by manual pipe cutting. CNC plasma machines, however, address this issue.

The following are some of the reasons that make these machines important:

- They reduce material waste.

- They improve joint accuracy.

- They lower labor dependency.

- They enhance the rate of production.

- They have consistent quality on batches.

Moreover, contemporary fabrication projects tend to involve complicated angles of the pipes. These designs can be achieved through CNC automation without manual measurements that have to be repeated.

Due to these advantages, most of the companies that CNC plasma cutting machine manufacturers are currently paying much attention to pipe profile solutions rather than flat cutting.

How does a CNC plasma pipe profile cutting machine work?

The working process is not complicated but very accurate. It is a software-controlled step-by-step system.

Step 1: Digital design input

The operator first loads a pipe design file to the CNC controller. The file contains cutting angles, dimensions, and shape information.

Step 2: Pipe positioning

The pipe is then put on rotating rollers. These rollers clamp the pipe and spin it in a smooth motion when cutting.

Step 3: Plasma arc generation

Subsequently, the plasma torch produces a high-temperature arc. This arc fuses the metal at the point of cut.

Step 4: CNC-controlled movement.

The CNC system regulates the movement of the torch and the rotation of the pipe. Therefore, the machine is able to cut curves, holes, and complicated joints precisely.

Step 5: Clean and accurate output

Finally, the machine finishes the cut with little slag. This saves the additional finishing work.

However, manufacturers such as Best Techno Dynamics develop machines that are not too automated and still provide operator control, which makes them reliable even in the case of long production cycles.

Main components involved in the cutting process

All CNC plasma pipe profile cutting machines are made up of well-coordinated components. All the components are essential to accuracy and performance.

Key components include the following:

- CNC controller – It serves as the brain of the machine.

- Plasma power source – Produces the cutting heat.

- Rotary pipe chuck – Grips and spins the pipe.

- Torch height control system – Keeps proper distance.

- Support rollers – Avoid pipe bending.

- Motion rails and motors – Guarantee smooth movement.

Therefore, an effective machine design enhances safety and minimizes failure. This is the reason why most users would want suppliers who have demonstrated experience, like the manufacturers of pipe cutting machine manufacturers in Gujarat that have good engineering habits.

Where are these machines commonly used?

CNC plasma pipe profile cutting machines are applied in industries whereby pipes have to fit the latter.

Typical areas of use are the following:

- Fabrication of structural steel.

- Oil and gas pipelines

- Power plant construction

- Shipbuilding industries

- Manufacturing of industrial furniture.

Moreover, these machines also come in handy where repetitive, identical cuts are necessary in a project. Automation will mean that every pipe is identical to the last one.

Due to the increasing demand, most CNC cutting machine manufacturers in India are increasing their pipe profile cutting solutions to cater to the local and international markets.

How to choose the right machine?

The selection of the appropriate machine will be based on your work needs. Nevertheless, the decision can be simplified by paying attention to several practical considerations.

Important factors to consider:

- Diameter and thickness of pipes.

- Type of material to be cut

- Required cutting accuracy

- Software ease of use

- Availability of after-sales support.

However, it is best to select a supplier that offers training and service support. Best Techno Dynamics is interested in long-term relations with its customers, which creates trust and reliability.

Even though it might be tempting to get cheaper machines, investing in quality will guarantee that there will be uniform outputs and reduced production hiccups.

Why Best Techno Dynamics?

A good machine supplier is known for its experience, technical expertise, and customer service. Best Techno Dynamics unites the three.

They focus on:

- Practical machine design

- User-friendly operation

- Strong build quality

- Practical fabrication requires it.

Additionally, their solutions are created based on industry feedback, meaning that machines can work effectively in real working conditions.

Conclusion

Frequently Asked Questions

-

What materials can a CNC plasma pipe machine cut?

It is effective in cutting mild steel, stainless steel, and other conductive metals.

-

Is CNC plasma cutting suitable for thick pipes?

Yes, it deals with medium to heavy pipes based on power capacity.

-

Does the machine require skilled operators?

Simple CNC controls are sufficient because of basic training.